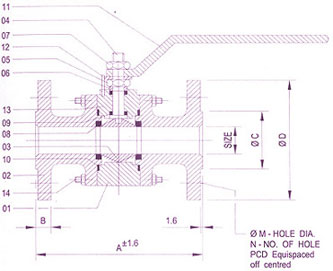

Three Piece Design (Flange End) Ball Valves

Suitable for : - Water, Oil and Gas

| No. | Description | Material | Qty. |

| 01 | Body | C.I. / C.S. / S.S. 304/ S.S. 316 | 1 |

| 02 | Body connector | C.I./C.S./S.S. 304 / S.S. 316 | 2 |

| 03 | Ball | AISI 304 / AISI 316 | 1 |

| 04 | Stem | AISI 304 / AISI 316 | 1 |

| 05 | Gland nut | AISI 304 / AISI 316 | 1 |

| 06 | Gland bush | AISI 304 / AISI 316 | 1 |

| 07 | Lock Nut | AISI 304 / AISI 316 | 1 |

| 08 | Seat Ring | PTFE | 2 |

| 09 | Stem Seal | PTFE | 2 |

| 10 | Body Sealent ring | PTFE | 1 |

| 11 | Wrench | C.S. / S.S. 304 / S.S. 316 | 1 |

| 12 | Stop | C.S. / S.S. 304 / S.S. 316 | 1 |

| 13 | Stopper pin | C.S. / S.S. 304 / S.S. 316 | 1 |

| 13 | Stud & Nut | C.S. / S.S. | - |

| Technical Data - Ball Valves | |

| Design & Manufacturing STD | API 602 |

| Testing & Inspection STD | API 598/ BS : 5146 |

| Face to Face | as per ANSI B 16.10 |

| End connections | Flanged as per ANSI B 16.5 |

| Drilling | Table D,E, F, ASA 150 #, ASA 300 # For Flange Dim. |

| Primary service reating & test pressure | ||||

| Class | Working press. | HYD. Test pressure | ||

| Body | Seat | Temp. | ||

| 150 | 150 PSIG | 425 PSIG | 300 PSIG | 200 °F |

| 300 | 300 PSIG | 1100 PSIG | 800 PSIG | 200 °F |

| Air Test - Seat 80 PSIG ± 10 PSIG | ||||

| Class - 300 | |||||||

| Size | A | B | øC | øD | øM | N | PCD |

| 15 | 141 | 14.2 | 35 | 95.0 | 16 | 4 | 66.5 |

| 20 | 153 | 15.7 | 43 | 117.0 | 19 | 4 | 82.5 |

| 25 | 164 | 17.5 | 51 | 124.0 | 19 | 4 | 89.0 |

| 32 | 177 | 19.0 | 64 | 133.0 | 19 | 4 | 98.5 |

| 40 | 191 | 20.5 | 73 | 155.5 | 22 | 4 | 114.0 |

| 50 | 215 | 22.0 | 92 | 165.0 | 19 | 8 | 127.0 |

| 65 | 240 | 25.0 | 105 | 190.5 | 22 | 8 | 149.0 |

| 80 | 282 | 28.5 | 127 | 209.5 | 22 | 8 | 168.0 |

| 100 | 306 | 32.0 | 157 | 254.0 | 22 | 8 | 200.0 |

| 125 | 380 | 35.0 | 186 | 279.4 | 22 | 8 | 235.0 |

| 150 | 402 | 36.5 | 216 | 317.5 | 22 | 12 | 270.0 |

| 200 | 421 | 41.0 | 270 | 381.0 | 25 | 12 | 330.0 |

| 250 | 458 | 47.5 | 324 | 444.5 | 29 | 16 | 387.0 |

| Class - 150 | |||||||

| Size | A | B | øC | øD | øM | N | PCD |

| 15 | 109 | 11.1 | 35 | 89.0 | 16 | 4 | 60.4 |

| 20 | 119 | 12.7 | 43 | 98.0 | 16 | 4 | 70.0 |

| 25 | 128 | 14.2 | 51 | 108.0 | 16 | 4 | 79.0 |

| 32 | 141 | 15.7 | 64 | 117.0 | 16 | 4 | 89.0 |

| 40 | 166 | 17.5 | 73 | 127.0 | 16 | 4 | 98.5 |

| 50 | 177 | 19.0 | 92 | 152.0 | 19 | 4 | 120.5 |

| 65 | 190 | 22.3 | 105 | 178.0 | 19 | 4 | 140.0 |

| 80 | 202 | 24.0 | 127 | 190.5 | 19 | 4 | 152.4 |

| 100 | 230 | 24.0 | 157 | 229.0 | 19 | 8 | 190.5 |

| 125 | 255 | 24.0 | 186 | 254.0 | 22 | 8 | 216.0 |

| 150 | 266 | 25.0 | 216 | 279.0 | 22 | 8 | 241.0 |

| 200 | 291 | 28.5 | 270 | 343.0 | 22 | 8 | 298.0 |

| 250 | 331 | 30.0 | 324 | 406.0 | 25 | 12 | 362.0 |

| All dimension are in mm | |||||||

Note : Due to constant up gradation, dimensions are subject to change by the manufacturer.