Butterfly Valves

Wafer type butterfly valve with an integrally bonded elastomer liner. Requiring absolutely no form of maintenance the UNIMAC is a perfect "Fit and forget"valve.

Available with either a flangeless or lugged body,in a size range of 50-600 mm,a pressure rating of up to PN 16 and offered with latching lever or actuation as well as different combination of disc and seat materials, "UNIMAC" is a truly versatile valve.

| Features | Benifts |

| Integrally bonded body seat | Easy And Trouble free mounting in the pipeline. No maintence. No tearing and distortion of liner. Exceptionally long seat life. Uniform sealing. Suitable for vacuum and high flow applications. |

| Stainless steel fully machined shaft(Optinal) PTFE coated | Permanent dry lubrication. Ease of operation. Prevents corrosion on shaft. |

| Primary and secondary seals integral with body lining | Ensures compatibility with media |

| Different disc and seat combination avaiable | Suitable for a wide range of applications. |

| Weatherseal feature | Atmospheric sealing to valve internals. |

| Spherical machined and polished disc(optional) | Ensures longer seat life,easier operation and tight shut-off. |

| Applications | ||||

| General Applications | Continuous Working Temperature Range | Maximun Working Pressure | Disc Material | Seat Material |

| Oils, fuels, water, air, gases, powders, pellets, slurries etc | Hydrocarbons (Except aromatics)- 10C to 90C Other Liquids - 10C to 80C Dry Services - 10C to 60C | 16 bar | Epoxy coated SG iron | Black Nitrile |

| Brines, sea water, estuary water, marine bilge and ballast systems | Liguids - 10C to 80C | 16 bar | Aluminium Bronze | |

| Steam, water, hot gases, powders, slurries and aqueous slurries of an abrasive nature | Liquids - 10C to 120C Dry services - 10C to 100C | 16 bar | Stainless stell Periphery Polished | General Purpose EPDM |

Additional Feature

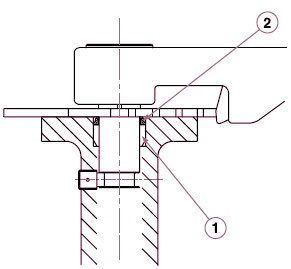

- O ring is provided to reduce the actuator torque and atmospheric sealing of the valve interior.

- It is provide for up to 600 mm dia.

- Long extended Neck for insulation purpose on request.

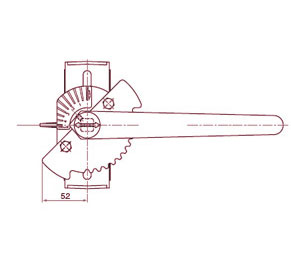

- Detachable hand lever to stop misuse of valve

- Special material combination as per buyers' request.

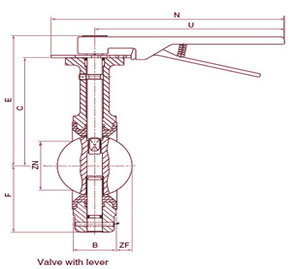

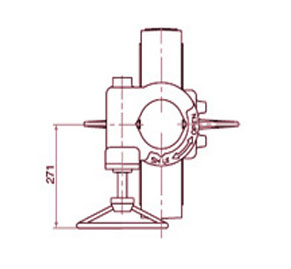

| Valve size mm (Inches) | 50 (2) | 65 (2.5) | 80 (3) | 100 (4) | 125 (5) | 150 (6) | 200 (8) | 250 (10) | 300 (12) | 350 (14) | 400 (16) | 450 (18) | 500 (20) | 600 (24) |

| B | 43.5 | 45.5 | 45.5 | 53 | 56.5 | 56.5 | 61 | 68.5 | 79 | 79 | 103 | 115 | 128 | 155 |

| C | 140 | 153 | 160 | 178 | 194 | 203 | 239 | 271 | 310 | 318 | 370 | 410 | 440 | 500 |

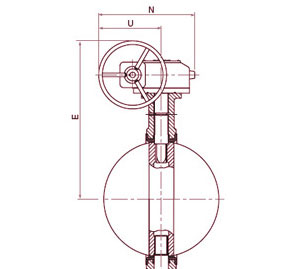

| E - Flow control lever Standard gear unit Heavy duty gear unit | 180 427 - | 193 440 - | 200 447 - | 218 465 - | 234 481 - | 243 490 - | 306 409 455 | 338 441 488 | 377 - 527 | - - 535 | - - 587 | - - 790 | - - 820 | - - 880 |

| F | 65 | 78 | 85 | 105 | 118 | 144 | 169 | 237 | 272 | 342 | 377 | 447 | 477 | 547 |

| H - Wafer flangeless Wafer lugged | 103 121 | 110 135 | 130 180 | 161 208 | 193 238 | 220 261 | 273 322 | 328 394 | 378 462 | 438 531 | 489 598 | 532 644 | 580 710 | 685 836 |

| N - Flow control lever Standard gear unit HEavy duty gera unit | 311 152 - | 311 152 - | 311 152 - | 311 152 - | 311 152 - | 311 152 - | 619 267 375 | 619 267 375 | 619 - 375 | - - 375 | - - 375 | - - 552 | - - 552 | - - 552 |

| U - Flow control lever Standard gear unit Heavy duty gear unit | 268 76 - | 268 76 - | 268 76 - | 268 76 - | 268 76 - | 268 76 - | 508 187 255 | 508 187 255 | 508 - 255 | - - 255 | - - 255 | - - 437 | - - 437 | - - 437 |

| ZN | 27 | 47 | 63 | 83 | 107 | 136 | 185 | 234 | 280 | 328 | 377 | 424 | 476 | 573 |

| ZF | 4 | 10 | 16 | 23 | 32 | 45 | 67 | 88 | 106 | 130 | 144 | 163 | 183 | 220 |

| Handwheel dia. - Standard gear unit - Heavy duty gear unit | 152 - | 152 - | 152 - | 152 - | 152 - | 152 - | 250 300 | 250 300 | - 300 | - 300 | - 300 | - 578 | - 578 | - 578 |

| Standards | ||

| Size(mm) | Standards | |

| Face to Face | 50 to 300 | BS 5155 - Wafer Short API 609 - Category A MSS SP 67 - Narrow Body ISO 5752 - Short IS 13095 |

| 350 to 600 | BS 5155 - Wafer Medium PI 609 - Category A(Except DN 350) MSS SP 67 - Wide Body ISO 5752 - Medium IS 13095 |

|

| Valve Design | BS 5155/IS 13095 - Specification for Butterfly Valves | |

| API 609 - Lug and Wafer type Butterfly Valves | ||

| MSS SP 67 - Butterfly Valves | ||

| ISO - Metal valves for use in flanged pipe system.Face to face and centre to face dimensions | ||

Flanges

The valves are of short pattern type and have been designed to fit between flanges without gaskets drilled to BS 10 Tables 'D','E',and 'F',ANSI 125/150, DIN PN 10/16, BS 4504(PN 10/16), Tables 6 yo 9 of IS : 6418, Table 10 to 20 of IS : 6392 and Tables 4 to 6 of IS : 1538

Accessories

UNIMAC butterfly valves can be supplied with factory fitted pneumatic, hydraulic or electric actuators along with other accessories such as limit switches,manual overrides,positioners etc. to form a complete flow control package. Heavy duty gear unit are supplied for valves to be fitted with electric actuators.

Installation, Operating and Maintenance instructiontions for the are available on request.

Note : Due to constant up gradation, dimensions are subject to change by the manufacturer.